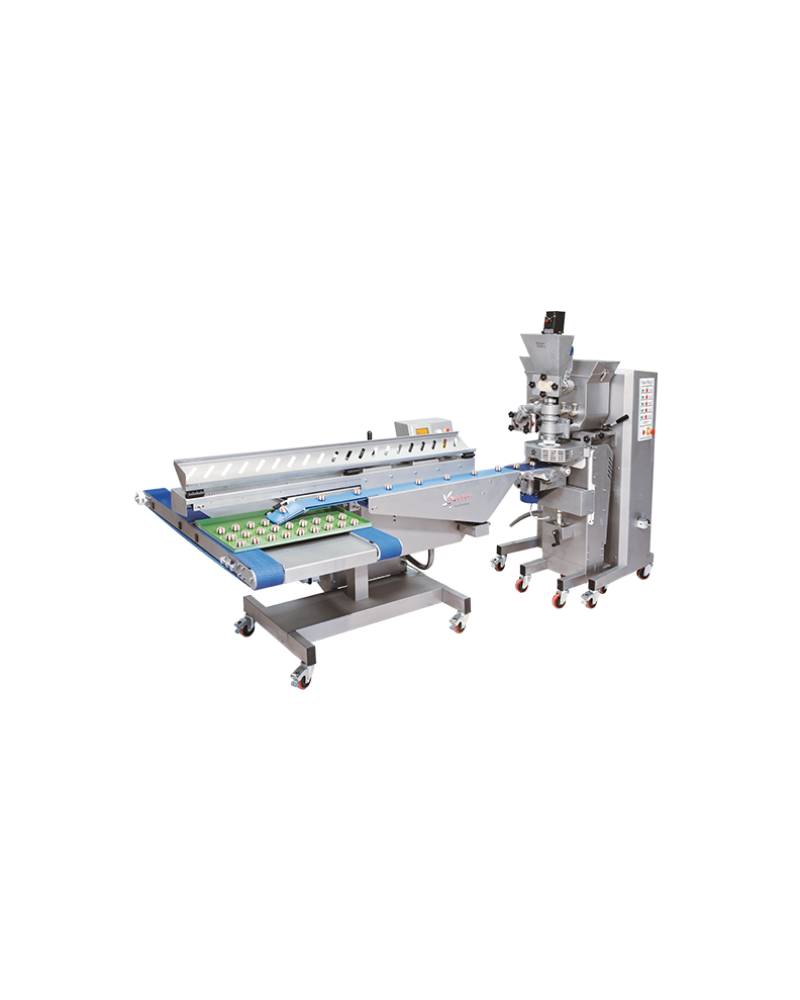

Automatic Dosing Machine with Solid Pieces (Formex)

- Brand: Formex

- Product Code: MA

This Automatic Doser Machine is the right machine for dosing soft or semi-soft dough, such as muffins, which incorporate pieces of solidswith a diameter of up to approximately 15 mm.It excels in the areas of speed, precision and ease of operation.The volumetric dosing is exact and guarantees the sam...

- This Automatic Doser Machine is the right machine for dosing soft or semi-soft dough, such as muffins, which incorporate pieces of solidswith a diameter of up to approximately 15 mm.

- It excels in the areas of speed, precision and ease of operation.

- The volumetric dosing is exact and guarantees the same amount of product is dosed in all nozzles.Homogeneous product.

- Flexible and expandable.

- Quick and easy change of the different accessories for multi-product work.

HMI PANEL FOR INTELLIGENT PRODUCTION MANAGEMENT

Through the touch screen we can control all of the machine’s functions:

- Recipe programming (create, rename, delete, duplicate).

- Management with multi-users and passwords with different access levels according to rank.

- Number of rows per tray and distance between products.

- Trays are moved forward, being positioned for filling and exiting upon completion.

- Option to create dosing patterns to adjust them to the different trays.

- Electronic control of tray presence, when the tray reaches the end of the conveyor belt the machine stops until the tray is removed.

- Single-dosing function for weight adjustment.

- Multi-dosing function: dosing is repeated in the same position on the tray.

- Independent conveyor function.

- Anti-drip control.

- Self-cleaning function.

- List of alarms that occurred on the machine.

- Control of activated automated inputs and outputs.

HOPPER

- The standard hopper can be exchanged for one with a larger capacity, it can be heated to work with products such as chocolate, and another hopper can even be added to work with dough with two colours.

- Option of using hoppers with different capacities.

- The heads can be interchanged with different configurations

- in terms of outlets and volumes.

- Removable, facilitates cleaning.

PNEUMATIC DEPOSITING

- The dosing volume and speed are independent and adjustable

- The doser system doesn’t harm the dough and allows us to work with very diverse products. The design of the nozzles allows us to deposit liquid dough, avoiding any dripping between the trays.

- The MA Doser Machine offers volumetric dosing in its different versions, both for the MA (pneumatic) and for the MAS (with servo motor)versions. The following table compares the main advantages of using a servo motor.

DOSING NOZZLES

- The machine can be used with different types of nozzles, adjustable nozzles with a variable centre, higher caliber pistons, anti-drip nozzles, etc.

- Some allow the passage of solid particles with a diameter of up to 15 mm.